The smallest LTT laser still has the complete powerful functions as other LTT products.

Rotary Attachment Connector for easy engravings of round surfaces

4 / 5 rating

SKU:

Brand :

Categories :

Tags :

Share item :

Features

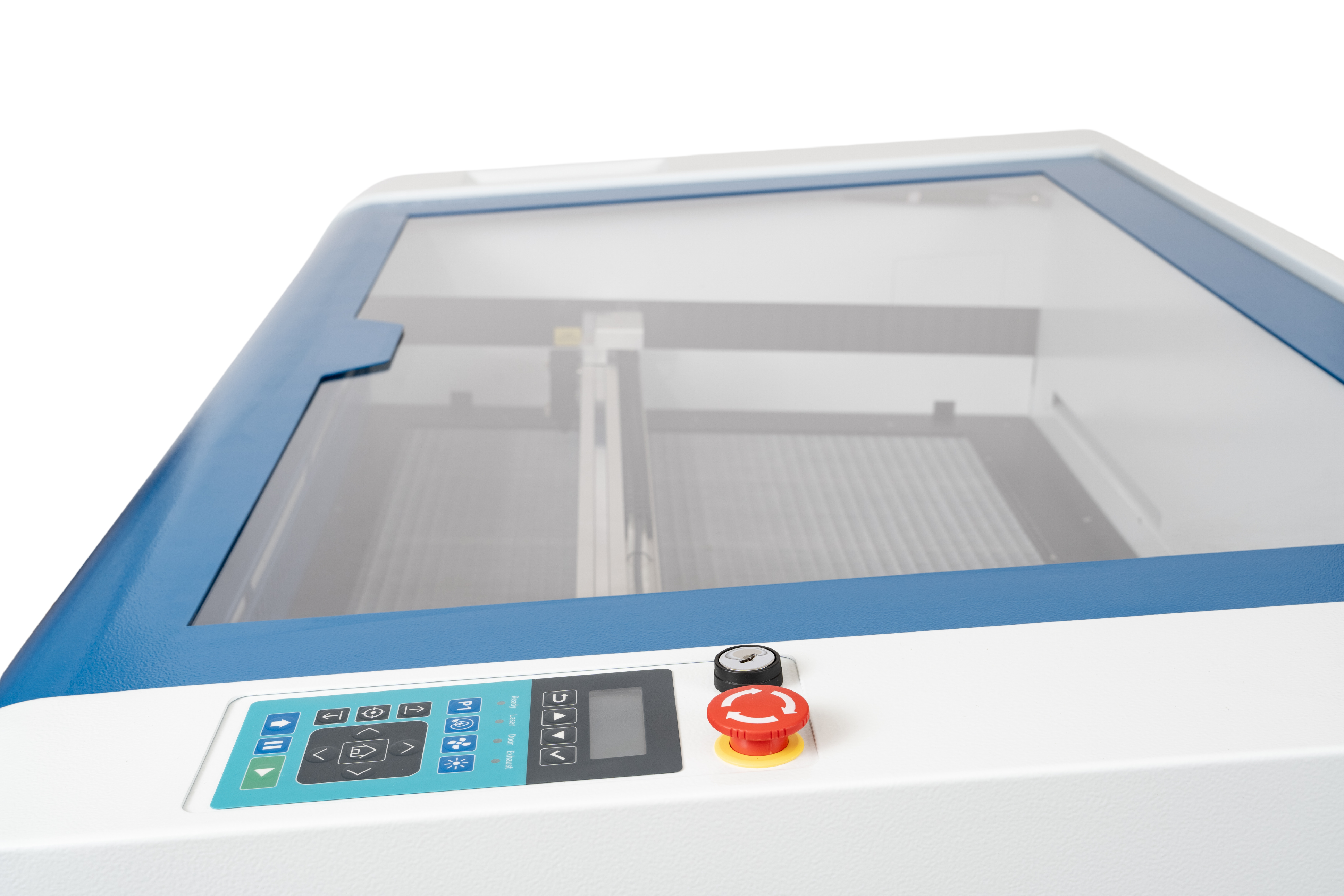

"The Q-Series is the pinnacle of LTT's professional laser engraving and cutting solutions, designed to deliver exceptional performance in a wide variety of industrial applications. This series stands out for its high-speed capabilities, precision, and user-friendly features, making it an ideal choice for businesses requiring reliable and efficient laser technology.

Key Features of the Q-Series:

- Unmatched Speed and Precision: The Q-Series boasts an impressive acceleration of up to 6G, reaching top speeds of 3150 mm/sec. This means that you can complete projects faster without sacrificing the quality of the cuts. The system’s 4000 PPI resolution ensures smooth edges, making it perfect for industries like signage, manufacturing, and woodworking.

- Advanced Fume Extraction and Air Assist: To ensure a safe and clean working environment, the Q-Series includes integrated fume extraction systems that effectively remove harmful fumes during the cutting and engraving processes. The air-assist function, which can be controlled through the machine’s software, helps improve the quality of the cuts while maintaining the longevity of the machine’s components.

- User-Friendly Interface: The Q-Series is equipped with an intuitive, icon-based control panel that simplifies operation. With features like cursor-controlled positioning, users can easily set up jobs, adjust parameters on the fly, and operate the machine with minimal training. This interface also allows for seamless integration with popular graphic software like CorelDraw and AutoCAD, streamlining your workflow.

- Customizable and Versatile: The Q-Series offers a variety of optional features to enhance its versatility. It includes different lens modules for various focal lengths, from 1.5"" to 2.5"", allowing for customization based on specific project requirements. Additionally, it supports rotary attachments, making it ideal for engraving non-planar objects like cylindrical items.

- Durability and Low Maintenance: Built for long-term use, the Q-Series is designed with durable components and features a refined internal structure to protect against damage from fumes and debris. The energy-saving mode also promotes eco-friendliness by reducing power consumption during idle periods, which helps to lower operational costs and extend the life of the machine.

- Enhanced Automation Options: For industries that require automated workflows, the Q-Series can be integrated with additional systems like vacuum pumps and air compressors. Its machine vision technology helps ensure precise cutting by automatically adjusting for alignment and deviation, making it an excellent choice for highly detailed and automated production environments.

In summary, the Q-Series is designed to offer high performance, versatility, and ease of use, making it a top choice for businesses looking to enhance productivity while maintaining exceptional precision in their laser-cutting projects."

One Touch and Job Done

The LTT developped Software is userfriendly as easy to start from Zero experience. It executes your engraving and cuttings Jobs with just one touch.

Smart Control Center

The Control pad directly placed on the machine enables parameter changes during job setups.

Pin-Type Auto Focus Sensor System

The System does automatically focus the leaser beam to the needed height to precisely fullfill all Jobs, so there are no manual adjustments needed.