As a laser machine owner, you want it to last as long as possible. Keeping it well-maintained is key to extending its life. By following simple tips, you can avoid damage and keep it running smoothly. This article will share essential maintenance advice to help you enjoy your machine for years.

By using these tips, you can cut down on downtime, boost productivity, and save on repairs. Regular maintenance is vital to extend your machine’s life. In the next sections, we’ll explore laser machine maintenance in-depth, giving you the knowledge to keep your machine running longer.

Introduction to Laser Machine Maintenance

Understanding the importance of maintenance is the first step. By focusing on it, you ensure your laser machine works at its best. Maintenance includes regular cleaning, checking for wear, and doing routine tasks to avoid damage.

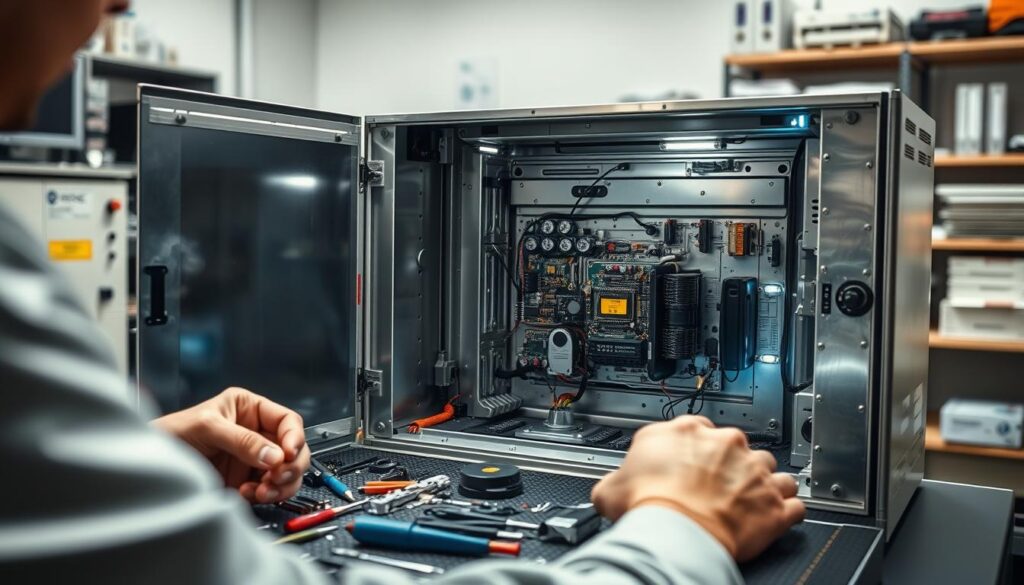

Understanding Your Laser Machine's Basic Components

Knowing your laser machine’s parts is key to keeping it running well. The main parts, like the laser source, beam delivery system, and control unit, work together. This ensures your laser machine performs at its best. Learning about these parts helps you spot problems early and prevent them.

Key Parts and Their Functions

The main parts of a laser machine include the laser resonator, mirrors, lenses, and cooling system. Each part is crucial for the machine’s performance. For example, the laser resonator makes the laser beam, while mirrors and lenses guide and focus it.

Common Wear Points to Monitor

It’s important to watch for wear on parts like the laser tube, mirrors, and lenses. This helps avoid damage and keeps your laser machine in top shape. By tracking these parts, you can catch issues before they get worse.

Understanding Performance Indicators

Knowing how to read performance indicators is vital. These include power output, beam quality, and processing speed. By keeping an eye on these, you can see where to improve and make your laser machine better.

Essential Laser Machine Tips for Daily Operation

Operating a laser machine daily requires some key tips and practices. These help your machine run well and last longer. A crucial laser machine tip is to clean and maintain it regularly, especially the lens and mirrors.

Here are some laser machine best practices to follow:

- Always operate and maintain according to the manufacturer’s instructions.

- Maintain a dry and clean environment for the machine.

- Examine and repair worn-out or damaged parts on a regular basis.

By following these laser machine daily operation tips and best practices, you can prevent common issues. This ensures your machine performs at its best. Make sure to consult your machine’s user manual whenever you need detailed instructions.

It’s also important to keep up with the latest laser machine tips and best practices. This way, you can optimize your laser machine daily operation and get the best results.

| Laser Machine Maintenance Tasks | Frequency |

|---|---|

| Daily cleaning | After each use |

| Weekly inspection | Every 7 days |

| Monthly deep cleaning | Every 30 days |

Proper Cleaning and Maintenance Schedule

To keep your laser machine in top shape, it’s key to have a cleaning and maintenance routine. This routine should cover daily, weekly, and monthly tasks. It helps your machine work well and last longer. A good maintenance schedule prevents damage and keeps your machine running smoothly.

Keeping your laser machine in good condition is vital. Daily cleaning, like wiping it down, and weekly checks for worn parts are important. A well-thought-out maintenance plan helps you keep up with your machine’s needs.

- Daily: Clean the machine and remove debris

- Weekly: Check and replace worn parts, such as filters and lenses

- Monthly: Perform deep cleaning and maintenance tasks, like cleaning the laser tube and mirrors

By sticking to this schedule and focusing on cleaning and maintenance, you can make your machine last longer. This ensures it works at its best.

Optimizing Your Workspace Environment

To make sure your laser machine works well, you need to set up a good laser machine workspace. This means creating a place that is steady and free from distractions. Think about the temperature, humidity, and air flow when you set up your area.

A great laser machine environment helps your machine last longer and work better. Keeping the temperature and humidity the same helps avoid damage and gets better cuts. Also, having good air flow stops fumes and dust from building up.

Here are some ways to laser machine optimization tips:

- Regularly clean and take care of your machine

- Watch and control the temperature and humidity

By doing these things, you can make a workspace that helps your laser machine work well. Always check the maker’s advice for your specific machine.

Improving your workspace is key to keeping your laser machine healthy and working well. By making a stable and controlled area, you help your machine perform at its best and last longer.

| Factor | Optimal Level | Impact on Laser Machine |

|---|---|---|

| Temperature | 60-80°F (15-27°C) | Affects cutting accuracy and speed |

| Humidity | 40-60% | Influences material cutting quality |

| Ventilation | Proper airflow and exhaust | Prevents fume accumulation and damage |

Maintaining Proper Laser Alignment

Keeping your laser machine aligned is key for its best performance and life. If it’s not aligned right, you might see less accuracy, lower productivity, and higher maintenance costs. To keep your laser machine running smoothly, regular maintenance and troubleshooting are a must.

Signs of Misalignment

Look out for signs like uneven cuts, poor beam quality, and more energy use. These signs mean your laser machine might be off-kilter. Regular checks can spot these issues early, saving time and extending your machine’s life.

Step-by-Step Alignment Process

Aligning the laser beam involves adjusting it to hit the target material just right. The steps can differ based on your laser machine’s model and type. Always check your user manual or get help from a pro for the right alignment and maintenance steps.

When to Seek Professional Help

If you’re not sure about aligning your laser machine, it’s best to get expert advice. A skilled technician can look at your machine and guide you on how to get it back in top shape.

| Laser Machine Alignment Checks | Frequency |

|---|---|

| Daily | Visual inspection of the laser beam and target material |

| Weekly | Check and adjust the laser beam focus and alignment |

| Monthly | Perform a thorough laser machine maintenance and troubleshooting check |

Managing Power and Cooling Systems

Keeping your laser machine’s power in check is key to its long life. It’s about watching how much energy it uses and keeping it cool. This stops it from getting too hot, which can harm its parts. Good cooling systems are vital to keep it running safely.

Managing your laser machine means checking its power and cooling often. Look at its temperature and energy use. This helps you spot and fix any problems, making it work better.

Here are some ways to manage power and cooling:

- Regularly clean the machine’s vents and filters to ensure proper airflow

- Monitor the machine’s temperature and adjust the cooling system as needed

- Optimize the machine’s energy efficiency by adjusting the power settings

By following these tips, you can make your laser machine last longer. It will also run at its best.

| System | Importance | Tips for Management |

|---|---|---|

| Power | High | Monitor energy efficiency, adjust power settings |

| Cooling | High | Regularly clean vents and filters, monitor temperature |

| Management | Critical | Regularly inspect systems, optimize performance |

Extending Lens and Mirror Life

To keep your laser machine running smoothly, it’s key to care for its lens and mirror. These parts are crucial for the quality of your laser’s beam. Regular cleaning helps prevent damage and keeps your machine in top shape.

Cleaning these parts needs care. Use a soft, dry cloth to remove loose dirt. Then, a special cleaning solution can tackle tough stains. Always check the manufacturer’s guide to avoid harming your optics.

Cleaning Optical Components

- Use a soft, dry cloth to wipe away loose particles

- Apply a specialized cleaning solution to remove stubborn stains

- Follow the manufacturer’s instructions for cleaning the laser machine lens and mirror

Storing your lens and mirror properly is also important. Keep them in a protective case or cover when not in use. This protects them from scratches and damage. By doing this, you ensure your laser machine’s beam quality stays high.

Preventive Maintenance Strategies

As a laser machine owner, you know how key laser machine preventive maintenance is. It keeps your equipment running smoothly for longer. Regular checks and maintenance stop sudden failures, cut down on downtime, and keep performance high. A good plan includes routine checks, scheduled upkeep, and fixing common problems.

Having a solid laser machine upkeep plan helps spot issues early. This means daily, weekly, and monthly tasks like cleaning, checking for wear, and updating software. Keeping up with maintenance lowers the chance of breakdowns and keeps your laser machine running well.

- Regularly cleaning the machine and its parts

- Looking for signs of wear, like misalignment or damaged parts

- Updating software and making backups

- Setting up regular maintenance with a skilled technician

By sticking to these laser machine maintenance strategies and keeping up with regular laser machine upkeep, you can make your equipment last longer. This reduces downtime and keeps your machine performing at its best.

Troubleshooting Common Issues

When your laser machine isn’t working right, it can be really frustrating. Knowing how to troubleshoot laser machines is key. This skill helps you find and fix common problems fast. Issues like poor cutting, uneven engraving, or machine malfunctions are common.

To fix these problems, you need to know what’s causing them. Sometimes, just tweaking the settings or cleaning the optics can solve the problem. But, if it’s a mechanical issue, you might need to replace parts or realign the machine.

Identifying the Root Cause

To solve common problems, you must find the main cause. Look at how the machine is performing, check the settings, and examine the parts. Signs of mechanical trouble include odd noises, vibrations, or overheating. Software issues can be fixed by updating the software or checking the settings.

Resolving Common Issues

After finding the main cause, you can start fixing it. Here are some common fixes:

- Cleaning the optics and mirrors

- Adjusting the machine’s settings

- Replacing worn-out parts

- Updating the software

By following these steps and doing regular maintenance, you can reduce downtime. This ensures your laser machine works its best. Good troubleshooting and repair can also make your machine last longer and work better.

Record Keeping and Maintenance Logs

Keeping accurate records is key to a laser machine’s health. By logging maintenance, you can spot issues early. This keeps your machine running well for longer.

It’s important to document every maintenance action. Record the date, time, and details of each task. This helps you plan better and avoid downtime.

Some important things to log are:

- Date and time of maintenance

- Type of maintenance performed

- Parts replaced or upgraded

- Any issues or problems encountered

- Results of performance tests

Good documentation is crucial for your machine’s longevity. It ensures your machine performs at its best. Prioritize keeping records and logs to save time and money.

Conclusion: Maximizing Your Laser Machine's Lifespan

To keep your laser machine lifespan long, you need a solid plan. This plan should include regular laser machine maintenance and smart laser machine optimization. Knowing your machine’s parts, cleaning it often, and keeping your workspace tidy are all important steps.

Don’t forget to check your machine regularly and fix problems early. Keeping detailed records of maintenance helps you track your machine’s health. This way, you can plan for upgrades or new equipment when needed.

Following these tips will help your laser machine last longer. This means you’ll get better results for your work. Stay on top of maintenance and your machine will keep performing well for many years.

FAQ

What are the key components of a laser machine?

A laser machine has several key parts. These include the laser source, mirror assembly, lens system, cooling system, and control electronics. Knowing how these parts work is key to keeping your laser machine in top shape.

How often should I clean and maintain my laser machine?

You should clean and maintain your laser machine regularly. This means daily cleaning, weekly upkeep, and monthly deep cleans. Keeping it well-maintained is vital for its long life.

What are some signs of laser misalignment, and how can I realign it?

Signs of misalignment include lower power, irregular beam shape, and poor cutting or engraving. To fix it, follow a detailed realignment process. If unsure, it’s best to get professional help.

How can I extend the lifespan of my laser machine’s lenses and mirrors?

To make your lenses and mirrors last longer, clean them properly and store them right. Also, replace them when needed. Good cleaning and care can extend their life a lot.

What are some common troubleshooting tips for laser machine issues?

For common problems, start by checking performance, mechanics, and software. Knowing how to solve these issues can keep your machine working well.

Why is it important to maintain detailed records and logs for my laser machine?

Keeping detailed records is essential. It helps track maintenance, monitor performance, and ensure your machine runs well. Good records can help you spot trends, solve problems, and plan for the future.