Welcome to our guide on using a laser engraving machine. You’ll learn how to use it safely and effectively. We’ll cover the basics and show you how to operate the machine. You’ll also learn about different techniques for laser engraving.

Learning laser engraving takes time and effort. But with our guide, you’ll be on your way to making beautiful designs. This guide is for both beginners and experienced users. It will help you get the most out of your machine and explore new techniques.

Understanding Laser Engraving Basics

Laser engraving is a cool way to make detailed designs on many materials. To start, you need to know the laser engraving basics. This includes how it works and the different laser engravers out there.

There are many laser engraving types, each with its own special features. You have CO2 lasers, fiber lasers, and diode lasers, to name a few. Knowing the differences helps you pick the best one for your project.

Laser engraving applications cover a wide range, from making industrial parts to creating art. It’s used for cutting and engraving metals, woods, and plastics. Plus, it’s great for making custom signs, logos, and designs.

Here are some important things to think about with laser engraving:

- Material compatibility: It’s key to pick the right material for your project.

- Resolution and accuracy: The quality of your final product depends on these.

- Safety precautions: Always follow safety rules and wear protective gear.

By learning about the laser engraving basics and exploring the different laser engraving types and laser engraving applications, you can make amazing designs and products.

| Laser Engraver Type | Application | Material Compatibility |

|---|---|---|

| CO2 Laser | Cutting and engraving woods, plastics, and fabrics | Organic materials, such as wood, plastic, and fabric |

| Fiber Laser | Cutting and engraving metals, such as steel and aluminum | Metallic materials, such as steel, aluminum, and copper |

| Diode Laser | Engraving and marking plastics, woods, and metals | Versatile, can be used with various materials, including plastics, woods, and metals |

Essential Safety Precautions for Laser Engraving

Laser engraving safety is key when using a laser engraving machine. To keep your workspace safe, follow important precautions. This means wearing safety glasses and gloves to avoid injuries from the laser and debris.

It’s also crucial to have good air flow to avoid breathing in harmful fumes and particles. A well-ventilated area helps remove dangerous materials, keeping you safe. Regular maintenance of your machine is also vital to avoid accidents and keep it running well.

Here are some must-follow laser engraving safety tips:

- Wear protective gear, like safety glasses and gloves

- Make sure your workspace has good air flow

- Follow all safety rules and guidelines from the manufacturer

- Keep your laser engraving machine well-maintained

By sticking to these precautions, you can have a safe and successful laser engraving project. Always put laser engraving safety first and take the right steps to prevent accidents and injuries.

Choosing the Right Materials for Your Project

Choosing the right materials for laser engraving is key to getting the best results. The material you pick can change the engraving’s quality, how fast it is done, and if it’s safe. We’ll look at the laser engraving materials you can use, including compatible materials and those to avoid.

Common compatible materials for laser engraving are wood, plastic, metal, and glass. The material thickness also matters, as thicker materials need more power and time. It’s important to know the material thickness guidelines for each material to get the best outcome.

- Research the compatible materials for your laser engraver

- Consider the material thickness guidelines for each material

- Choose materials that are safe to engrave and suitable for your project

By picking the right laser engraving materials and following the material thickness guidelines, you can get professional-looking results. This ensures a safe and successful engraving process.

| Material | Compatible | Material Thickness |

|---|---|---|

| Wood | Yes | 1/4 inch to 1 inch |

| Plastic | Yes | 1/16 inch to 1/4 inch |

| Metal | Yes | 1/16 inch to 1/4 inch |

| Glass | Yes | 1/16 inch to 1/4 inch |

Setting Up Your Workspace

A well-organized laser engraving workspace is key for safe and efficient work. When setting up your workspace setup, remember to focus on ventilation, storage, and cable management. A clean space helps avoid accidents and makes working more comfortable.

To make the perfect laser engraving workspace, here are some tips:

- Choose a well-ventilated area to prevent inhalation of fumes and particles.

- Invest in a sturdy table or workbench to support your laser engraver and materials.

- Organize your cables and wires to prevent tripping hazards and electrical issues.

By following these tips, you can set up a safe and productive workspace setup for your laser engraving projects. Always put safety first and aim for the best quality in your work.

With a well-organized laser engraving workspace, you can focus on making high-quality engravings. Enjoy the process of bringing your ideas to life.

| Workspace Setup Tips | Benefits |

|---|---|

| Proper Ventilation | Prevents inhalation of fumes and particles |

| Sturdy Table or Workbench | Supports laser engraver and materials |

| Cable Management | Prevents tripping hazards and electrical issues |

How to Use a Laser Engraving Machine: Complete Operation Guide

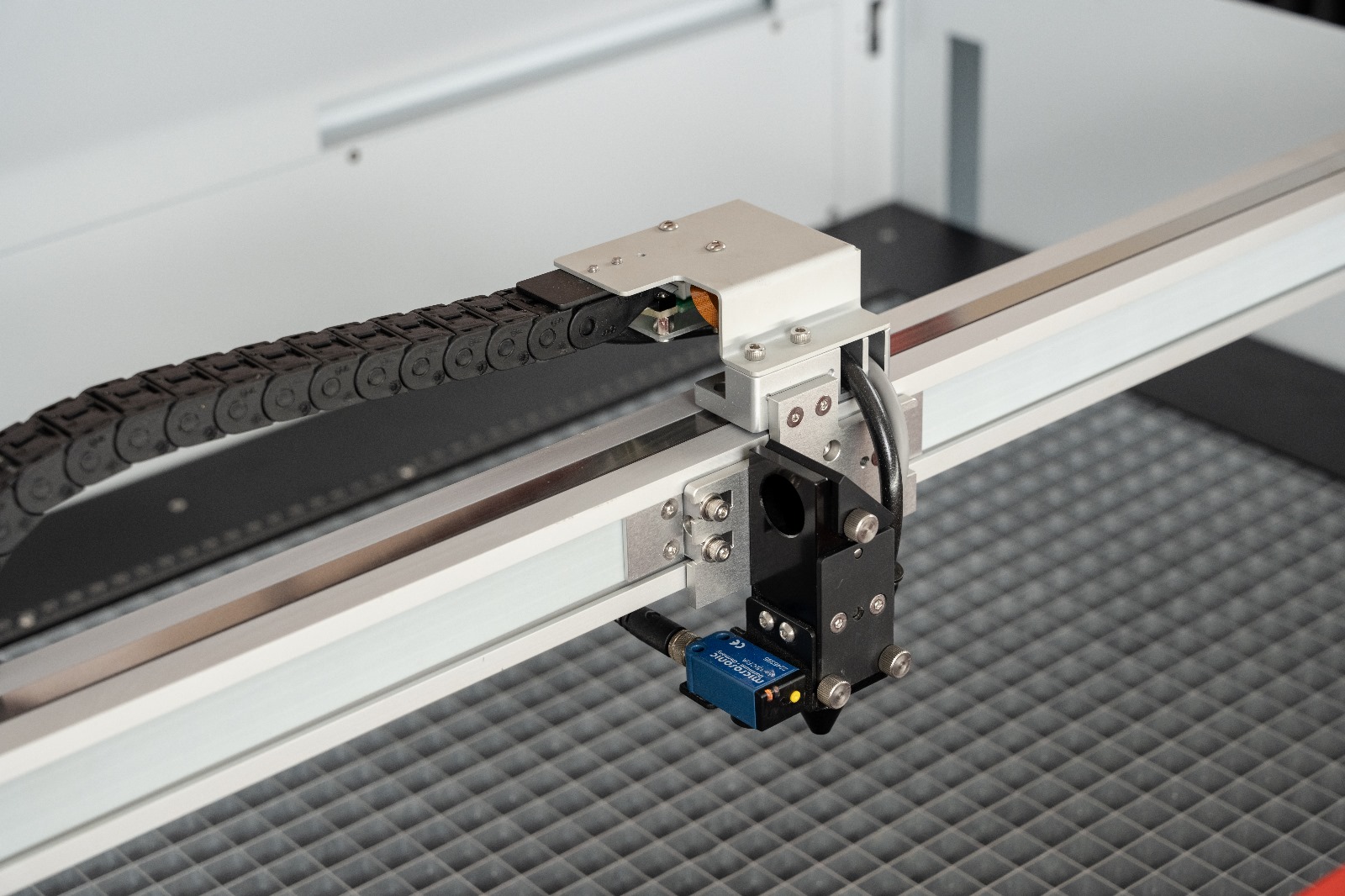

To start using a laser engraving machine, you need to know the machine components and how they work. The control panel navigation is also key. It lets you change settings and watch the engraving.

Using a laser engraving machine involves a few steps. First, set up the machine. Then, load your materials. Lastly, adjust the power and speed. Knowing these steps and how to use the control panel helps you get great results.

Some important things to remember when using a laser engraving machine include:

- Understanding the different modes of operation, including raster and vector modes

- Adjusting power and speed settings to optimize results for specific materials

- Monitoring the engraving process to ensure accuracy and quality

By following these tips and understanding the machine components and control panel navigation, you can become a pro at using a laser engraving machine. You’ll be able to make high-quality engravings with ease.

Preparing Your Design Files

For laser engraving, the right design files are key to great results. Laser engraving design files are essential. Knowing the compatible file formats your engraver can use is crucial.

Adobe Illustrator and CorelDRAW are top picks for making these files. They let you create and tweak designs with care. This makes sure your files are engraving-ready.

Compatible File Formats

Laser engravers work with many file types, like SVG, DXF, and PDF. Always check your machine’s specs to find out which formats it supports.

Design Software Options

When picking design software, think about its features and if it works with your engraver. Here are some favorites:

- Adobe Illustrator

- CorelDRAW

- Gravit Designer

Image Resolution Requirements

The needed image resolution for laser engraving depends on your machine and what you want to achieve. Usually, a higher resolution means more detailed engravings.

Knowing about file formats, design software, and resolution needs helps you make top-notch laser engraving files. These files will lead to amazing results.

| Design Software | Compatible File Formats | Image Resolution Requirements |

|---|---|---|

| Adobe Illustrator | SVG, DXF, PDF | 300 DPI |

| CorelDRAW | SVG, DXF, PDF | 300 DPI |

Calibrating Your Laser Engraver

Calibrating a laser engraver is key to getting precise results. The calibration process adjusts the machine’s settings. This ensures the laser beam is aligned and focused right.

This step is vital for quality engravings and to avoid damage. It keeps the machine and materials safe.

To start calibrating, check the machine’s manual for steps. You’ll need to adjust the laser beam’s focus and align mirrors. Also, set the right power and speed for your project.

Remember, calibrate your machine often. This keeps it accurate and precise over time.

Here are some tips for calibration:

- Always follow the manufacturer’s instructions for calibration.

- Use a calibration test pattern to ensure accuracy.

- Regularly clean and maintain the machine to prevent damage and ensure optimal performance.

By following these tips and calibrating regularly, your machine will work smoothly. It will also produce high-quality results. Always follow the manufacturer’s instructions and be safe when using the machine.

| Calibration Step | Description |

|---|---|

| Focus Adjustment | Adjust the laser beam’s focus to ensure proper alignment. |

| Mirror Alignment | Align the machine’s mirrors to ensure accurate beam reflection. |

| Power and Speed Settings | Set the correct power and speed settings for the specific material being used. |

Loading and Positioning Materials

Properly loading laser engraving materials is key to getting great results. It’s important to know how to place materials for the best engraving. Think about the material type, thickness, and what you want to achieve.

How you place materials is very important in laser engraving. To get the best results, follow these tips:

- Place the material on a flat surface to prevent uneven engraving.

- Ensure the material is securely positioned to avoid movement during the engraving process.

- Use a material that is compatible with the laser engraver and the desired engraving outcome.

Adjusting the focus distance is also crucial for precise engraving. The focus distance should match the material’s thickness and your engraving goals. It’s also important to test the material’s position to make sure it’s right.

By following these guidelines and using the right techniques, you can get top-notch laser engraving. Always remember to follow safety rules and use materials that work well together for a successful project.

| Material | Thickness | Engraving Outcome |

|---|---|---|

| Wood | 1/4 inch | High-contrast engraving |

| Plastic | 1/8 inch | Low-contrast engraving |

| Metal | 1/2 inch | Deep engraving |

Running Your First Engraving Job

To start your laser engraving first job, you need to set up your machine and design file. This is key for a successful engraving job setup. First, load your design file into the machine’s software. Make sure it’s in a format the machine can use.

Then, adjust the machine’s settings for your material and design. You might need to change the power, speed, and focus distance. Keep an eye on the laser engraving first job and tweak settings as needed for the best results.

Some important things to think about for your engraving job setup are:

- Material thickness and compatibility

- Design resolution and complexity

- Machine settings and calibration

By planning well and executing your laser engraving first job carefully, you’ll get great results. Always follow safety rules and the machine’s instructions.

Troubleshooting Common Issues

Working with laser engraving machines can sometimes lead to problems. Laser engraving troubleshooting helps find and fix these issues. Issues can include uneven engraving, wrong depths, or machine errors like faulty mirrors.

To solve these problems, it’s key to know what’s causing them. Check the machine’s settings, keep it well-maintained, and make sure materials are right. Common issues can often be fixed by tweaking settings or cleaning and calibrating the machine.

- Quality problems: Check the machine’s settings, ensure proper maintenance, and verify material compatibility.

- Machine errors: Check for faulty mirrors, misaligned beams, or other mechanical issues.

- Material-related issues: Ensure that the materials being used are compatible with the machine and follow the recommended settings.

By following these steps and understanding common laser engraving problems, you can quickly solve them. This ensures your work is top-notch. Regular laser engraving troubleshooting and maintenance can also prevent issues and make your machine last longer.

| Issue | Cause | Solution |

|---|---|---|

| Uneven engraving | Incorrect power settings | Adjust power settings |

| Faulty mirrors | Misaligned or damaged mirrors | Replace or realign mirrors |

| Material incompatibility | Using incorrect materials | Choose compatible materials |

Maintaining Your Laser Engraver

Regular laser engraver maintenance is key to keeping your machine running well. It helps your engraver last longer and work better. A clean and well-maintained laser engraver makes sure your engravings look great and avoids mistakes or damage.

To keep your engraver in top shape, make a maintenance schedule. This should include cleaning, oiling, and updating your machine.

Some important tasks for your maintenance schedule are:

- Cleaning the machine and its parts often

- Oil moving parts to stop wear and tear

- Update the machine’s software and firmware for best performance

By sticking to a regular laser engraver maintenance plan, you can avoid common problems. This ensures your machine keeps making high-quality engravings. Always check your machine’s manual for the right maintenance steps.

With a well-kept laser engraver and a steady maintenance schedule, you’ll get the best performance. You’ll also cut down on downtime and make top-notch engravings for years.

| Maintenance Task | Frequency |

|---|---|

| Cleaning the machine | Weekly |

| Lubricating moving parts | Monthly |

| Updating software and firmware | Quarterly |

Advanced Engraving Techniques

To improve your laser engraving skills, you need to learn advanced techniques. Laser engraving advanced techniques help you make complex designs and effects. One key method is multi-layer engraving, where you engrave different layers to get a 3D look.

When using advanced techniques, keep these points in mind:

- Material selection: The right material is key for the desired look.

- Design preparation: Your design files must be ready for engraving.

- Machine settings: Adjusting power and speed affects the engraving quality.

Learning laser engraving advanced techniques, like multi-layer engraving, lets you create detailed designs. With time and effort, you’ll make amazing pieces. Your skills and creativity will shine through.

Conclusion

As we wrap up our guide on using a laser engraving machine, we hope you’re excited to start creating. Laser engraving is a skill that grows with practice. So, don’t hesitate to try new things and adjust your settings.

Whether you’re working with wood, metal, or exploring 3D engraving, enjoy the learning. Each project will teach you something new. Stay curious, patient, and always keep safety in mind as you improve.

For more inspiration and help, check out online forums and tutorial videos. The laser engraving community is full of useful tips and experiences. Keep honing your skills, and you might soon create amazing pieces that impress everyone.

FAQ

What is laser engraving?

Laser engraving uses a strong laser to carve designs, text, or images on different materials. This includes metal, wood, plastic, and more.

What types of laser engravers are available?

There are CO2 lasers, fiber lasers, and diode lasers. Each has its own special features and uses.

What are the common applications of laser engraving?

It’s used for many things. Like making custom items, marking industrial goods, creating signs, and making awards.

What safety precautions should I take when using a laser engraver?

Wear protective gear and make sure the area is well-ventilated. Follow the maker’s guidelines to stay safe.

What materials are compatible with laser engraving?

You can use wood, acrylic, glass, metal, leather, and some plastics. But avoid PVC.

How do I set up a workspace for laser engraving?

Your workspace should be organized. It needs good air flow, cable management, and places to store things.

What are the key components of a laser engraving machine?

A laser engraver has a laser, a way to move it, a work area, and a control panel. This panel lets you adjust settings.

What file formats are compatible with laser engraving?

You can use SVG, DXF, EPS, JPEG, and PNG files. These are vector and raster formats.

How do I calibrate my laser engraver?

To calibrate, adjust the laser power, focus, and alignment. This ensures your engravings are precise and consistent.

How do I properly load and position materials for laser engraving?

Place materials carefully and adjust the focus. Make sure the position is accurate for the best results.

What are some common troubleshooting tips for laser engraving issues?

For problems, check the quality, fix machine errors, and deal with material issues. Regular maintenance and calibration help too.

How do I maintain my laser engraver?

Clean and lubricate it regularly. Keep up with updates and make a maintenance plan. This keeps it working well.

What are some advanced laser engraving techniques I can try?

Try multi-layer engraving, 3D methods, and color fills. These techniques can make your designs more complex and beautiful.