Buying a laser machine is a big deal for businesses. There are laser cutting machine deals and budget laser engraver options out there. But, finding them takes some planning. This article’s laser machine purchase guide will help you save money without losing quality.

Making smart choices can really cut costs. By looking into affordable laser equipment and staying up-to-date with trends, you can stretch your budget. This way, you ensure your business stays efficient in the long run.

Understanding Laser Machine Types and Price Ranges

Choosing the right laser machine starts with knowing your options. Let’s break down the main types and their typical costs to match your budget and needs.

Entry-Level vs. Industrial Laser Machines

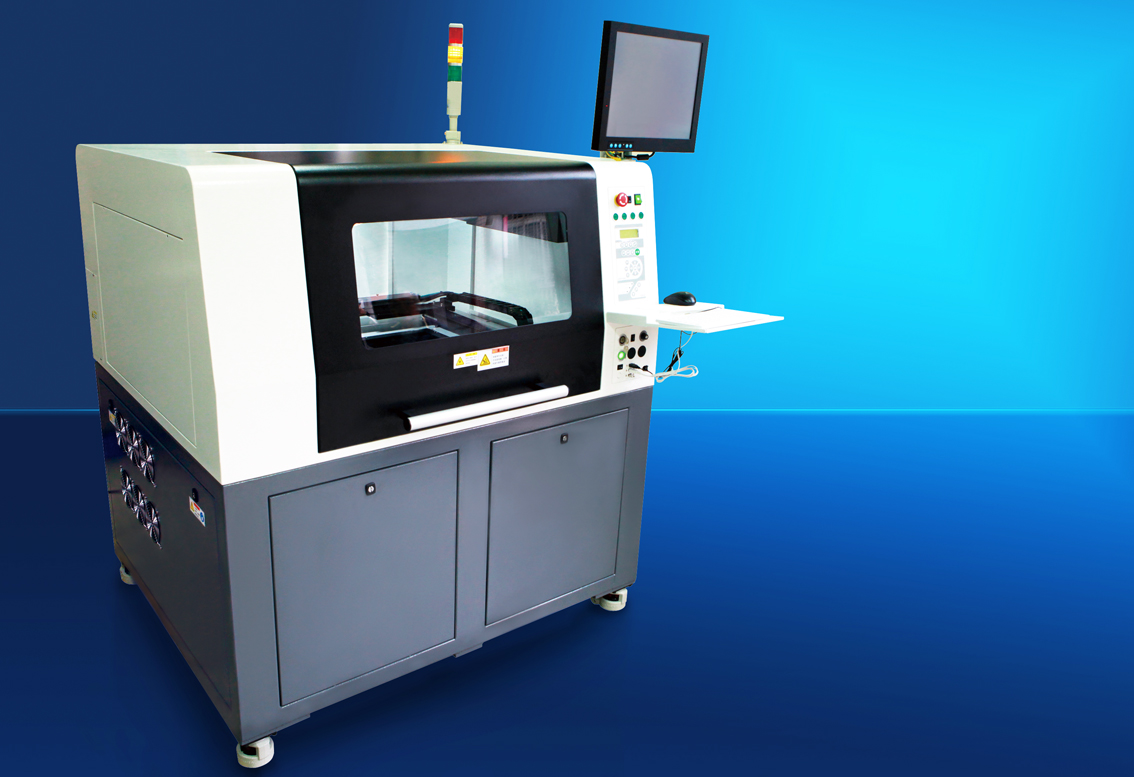

Entry-level laser cutters cost between $5,000 and $20,000, perfect for small workshops or prototyping. Industrial laser machines, priced at $50,000+, are built for 24/7 use. Think: Do you need to make lots of items or just a few?

Features That Impact Pricing

- Work area size: Larger tables = higher cost

- Power wattage: 40W entry-level vs. 5000W industrial systems

- Automation controls: Touchscreens or robotic arms add to laser machine features pricing

Focus on features that directly improve your workflow—don’t pay for extras you won’t use.

Research Strategies Before Making a Purchase

Effective laser machine buyer research begins with understanding your business’s needs. Ask yourself: What materials will you cut every day? How many hours will the machine run each day? This helps avoid buying more than you need.

Use pre-purchase laser research tools like comparison charts and laser equipment reviews from trusted sources. Look at reviews from Laser Focus World or industry forums.

- Begin with laser machine research methods that include hands-on demos. Test cutting samples to see how the machine performs in real life.

- Make spreadsheets to compare laser cutters side-by-side. Note their speed, power, and maintenance costs.

Read laser equipment reviews from unbiased sources. Check forums like Lasers and Optics Discussion for user experiences. Also, contact vendors for case studies of similar businesses. This can reveal costs or benefits not mentioned in brochures.

“80% of buyers save over $5,000 by vetting at least three brands through peer recommendations,” says Advanced Laser Solutions’s technical director. “Skipping this step risks compatibility issues down the line.”

Combine laser machine research methods with budget planning. Look at maintenance schedules and warranty terms to avoid surprises after buying. The effort put into pre-purchase laser research ensures the machine fits your needs, saving money in the long run.

Timing Your Purchase for Maximum Savings

Smart buyers know the best time to buy a laser machine is during strategic moments. Seasonal trends and industry events offer chances to get great deals without losing quality. Here’s how to find the peak savings periods for your purchase.

End-of-Quarter and Year-End Deals

Manufacturers work hard to meet sales targets at the end of each quarter and year. Year-end laser deals are common as companies try to clear inventory and increase revenue. December and March are the best months for laser machine seasonal discounts.

Sales teams might offer extended warranties or service packages for free during these times.

Trade Show Discounts and Special Events

Trade shows like SPIE Photonics West or Laser World of Photonics offer trade show laser equipment savings not found elsewhere. Attendees can find best time to buy laser machine deals, including software bundles or installation support. Remember, negotiate terms before attending to compare offers.

Manufacturer Promotions and Alerts

Sign up for emails from brands like Coherent, IPG Photonics, or Trumpf to track manufacturer laser promotions. These updates highlight limited offers tied to model launches or inventory shifts. Set reminders for Q4 and Q1 sales cycles when rebates peak.

- Check manufacturer newsletters for holiday season specials

- Follow @LaserTechDeals on social media for flash sales alerts

- Ask sales reps about unadvertised end-of-quarter incentives

Timing isn’t just about dates—it’s about knowing when suppliers want to move inventory. Plan purchases during these windows to maximize savings without compromising on technology or support.

Comparing New vs. Used Laser Machines

Deciding between a new or used laser machine involves looking at used vs new laser machine advantages and disadvantages. Used laser machine value can save you 30–60% of the cost. Yet, it’s crucial to consider second-hand laser reliability.

New machines come with warranties and the latest technology. On the other hand, used systems might need more checks.

Benefits and Risks of Pre-Owned Equipment

Used systems can save you money upfront. But, they come with risks. Second-hand laser reliability depends on how well they were maintained.

There’s a chance for limited warranties, repairs, and compatibility issues. Yet, used laser machine value is attractive for those watching their budget.

Refurbished Options: A Middle-Ground Approach

Think about refurbished laser equipment for a balance. It offers savings with some upgrades. Factory-certified models often have tested parts and warranties.

Dealers like Trumpf or Epilog sell refurbished units at 40–50% off. This option is both affordable and reliable.

What to Inspect When Buying Used

- Look at pre-owned laser cutter inspection reports for wear on the motion system.

- Make sure the laser tube’s lifespan and calibration are accurate.

- Test the cooling systems and electronics for steady performance.

- Review maintenance logs and ask for service history documents.

Always have a certified technician check second-hand laser reliability. A detailed inspection can avoid hidden costs and ensure the machine works well for a long time.

How to Save Money on Your Next Laser Machine Purchase

Save big with laser machine discount strategies that offer great value without losing quality. Begin by picking affordable laser machine options that fit your needs perfectly. Don’t spend more on features you won’t use—stick to the basics first.

- Choose open-architecture systems for flexibility. These systems allow you to add upgrades later, saving you money on proprietary add-ons.

- Trim non-essentials like auto-focus lenses or rotary chucks. Add these laser cutter budget tips when your budget grows.

- Domestic brands save more. U.S.-based makers like Universal Laser Systems might have higher prices but lower shipping and duty costs.

| Open-architecture | Proprietary Systems |

|---|---|

| Flexible, third-party upgrades | Vendor-controlled add-ons |

| Lower long-term costs | Potential hidden fees |

Save even more by looking at demo units or last year’s models. They often have 60-80% discounts but still work well. When you’re ready to buy, bundle your order with service contracts for more laser purchase savings tips. Focus on affordable laser machine options by choosing specs that meet your immediate needs.

Negotiation Tactics with Suppliers

Getting a good deal on laser machine price negotiation takes time and effort. Good supplier negotiation strategies can reveal savings in vendor relationships. Start by building trust—loyal clients get better deals. Here’s how to get the most savings:

Building Relationships with Vendors

- Ask for vendor relationship discounts after buying from them several times. Many suppliers give 5-10% off for big orders or long-term deals.

- Discuss early payment terms or longer warranties. Long-term partnerships can lower costs in the future.

Laser Equipment Bundle Deals

Buying laser equipment bundle deals with extras can save 10-15%. For example:

- Get machines with maintenance contracts.

- Include software licenses or spare parts with your first order.

Leveraging Competitive Quotes

Use competitive laser machine quotes to get better deals. A simple script can help:

“We’re reviewing offers from three suppliers. Could you match [X Company]’s quote on delivery timelines?”

Keep negotiations professional. Vendors expect comparisons but value honesty.

Financing Options and Tax Benefits

Choosing the right laser machine financing can save you money. Look at equipment leasing vs purchasing to fit your budget. Leasing spreads out payments, while buying gives you ownership and tax perks.

- Laser equipment loans have fixed terms (3–7 years) with interest rates from 6% to 12%.

- Leasing offers flexible terms but might not give you long-term ownership benefits.

- Manufacturer financing programs often include maintenance packages.

| Option | Leasing | Purchasing |

|---|---|---|

| Upfront costs | Lower monthly payments | Higher initial expense |

| Tax benefits | No Section 179 tax deduction | Full deduction eligibility |

| End-of-term options | Return/repurchase | Ownership and resale value |

Use the Section 179 tax deduction to your advantage. For instance, buying a $50,000 laser system could let you deduct the full amount in year one. This reduces your taxable income by that amount. It can cut your effective costs by up to 21% (depending on your tax rate).

Look into the tax advantages of buying laser equipment compared to renting.

“Smart financing and tax planning can cut total costs by 15–30%,” says industry analyst Sarah Thompson. “Always compare laser equipment loans with current market rates.”

Get advice from a tax advisor to save more. Deciding between leasing and buying depends on your cash flow and long-term goals. Finding the right balance between tax advantages and payment flexibility leads to better investments.

Maintenance Considerations and Long-term Savings

Proper care for your laser machine isn’t just about repairs—it’s a strategy to reduce laser operating expenses long-term. Routine upkeep and smart planning keep costs low and productivity high.

Staff Training for Efficiency

Invest in staff training laser equipment to minimize errors. Trained teams:

- Reduce material waste by 15–25% through precise operation.

- Avoid costly mistakes that damage parts or slow production.

Training programs pay off quickly—every dollar spent on training saves $3 in repair costs.

By combining these steps, businesses can slash laser machine maintenance costs while extending machine lifespan. Prioritize maintenance as part of your budget plan, not an afterthought!

Conclusion

When looking at laser machine costs, it’s key to weigh upfront costs against long-term savings. Investing wisely in laser equipment means thinking about all stages, from buying to upkeep. When choosing a laser cutter, focus on what you need to make, not just the cheapest option.

Follow these tips to get the most out of your laser machine: look into warranties, compare deals at the end of the quarter, and consider refurbished models. Also, ask for service agreements that last several years. Don’t forget to include training and parts costs in your total expense. Even small savings can add up over time.

Leave a comment with your own cost-cutting tips. Sharing experiences can reveal new ways to save without losing quality. Whether you’re upgrading a small business or growing a large operation, these strategies help match your budget and goals.

FAQ

Is it better to buy a new or used laser machine?

It depends on your budget and needs. New machines have the latest tech and warranties. But, used machines can save you 30-60% and still offer good value. Think about maintenance costs and warranties before choosing.

How can I ensure I’m getting the best price on a laser machine?

Timing is key. Look for end-of-year sales and trade show deals. Also, be ready to negotiate with suppliers to get the best price.

What are some effective negotiation tactics when dealing with laser machine vendors?

Building strong vendor relationships can lead to exclusive deals and better support. Ask for bundle deals that include software or training. Use competitive quotes to get the best price from vendors.

How does financing work for laser machine purchases?

Financing options include loans, leases, and manufacturer programs. Each has its own benefits and drawbacks. Research them well. Also, look into Section 179 tax deductions to lower your costs.

How important is preventative maintenance for my laser machine?

Preventative maintenance is crucial to save money. Regular upkeep prevents costly repairs and keeps your machine running smoothly. Create a maintenance schedule and stock up on spare parts to keep your machine in top shape.