Thinking about getting a laser cutting machine? The cost is a big deal. Prices vary a lot, based on the machine’s type and quality. Knowing the cost helps you make a good choice. You’ll learn what affects the price and how to pick the best one for you.

The cost isn’t just the upfront price. It’s also about what you’ll spend over time. With more people wanting laser cutting, it’s key to understand the costs. You’ll find out what impacts prices and how to pick the right machine for your needs and budget.

Understanding Laser Cutting Machine Basics

Exploring laser cutting means knowing the basics of laser cutting technology. This tech uses a strong laser to cut through many materials with great precision. The types of laser cutting machines vary by power source, cutting head, and control system.

Laser cutting applications are vast. It can cut metal, wood, fabric, and leather. Some common uses include:

- Cutting and engraving metal sheets

- Crafting custom wood designs

- Creating intricate fabric patterns

To grasp what laser cutting machines can do, let’s look at the types of laser cutting systems out there:

| System Type | Description |

|---|---|

| QLaser | Ideal for cutting wood, fabric, and leather |

| iLaser | Suitable for cutting metal and other high-reflectivity materials |

Entry-Level Laser Cutting Machine Prices

Looking for an entry-level laser cutting machine? You’ll find many options that fit your budget and needs. Laser cutter prices change based on the machine’s features and brand. As a beginner, aim for an affordable laser cutting machine that balances quality and cost.

When picking an entry-level laser cutting machine, think about what you need to cut and the precision you want. Also, check if the laser cutter prices match your budget. Luckily, there are many affordable laser cutting machines out there, making it easier to find the right one.

Here are some benefits of using an entry-level laser cutting machine:

- Cost-effective: Entry-level laser cutting machines are cheaper than professional ones.

- Easy to use: Many entry-level laser cutting machines have simple software and interfaces.

- Versatile: Entry-level laser cutting machines can handle cutting, engraving, and marking.

By choosing the right entry-level laser cutting machine for your needs, you can enjoy laser cutting tech without spending too much. With laser cutter prices getting better, finding an affordable laser cutting machine is easier than ever.

Professional and Industrial Laser Cutting Machine Costs

Thinking about getting a laser cutting machine? It’s key to know the costs of professional and industrial models. These machines are perfect for businesses needing precise and efficient cuts. They’re a big investment but can pay off for companies using custom cutting solutions.

For small businesses, expect to spend between $10,000 to $50,000 on a basic industrial laser cutting machine. Prices change based on the machine’s features and capabilities. For instance, a machine with better software and a bigger cutting bed will cost more. Here are some things to think about when looking at professional laser cutting machine costs:

- Machine type: Industrial laser cutting machines vary from basic to high-end, affecting price.

- Cutting capabilities: Machines with advanced software and bigger cutting beds cost more.

- Customization options: Custom laser cutting solutions are pricier but offer more precise cuts.

Don’t forget about ongoing costs and maintenance needs of a professional laser cutting machine. Regular upkeep can prevent expensive repairs and extend the machine’s life. With proper care, a professional laser cutting machine can serve your business well for years.

Understanding the costs and what professional and industrial laser cutting machines can do helps you choose the right one for your business. Whether you need a basic machine or a custom solution, there are many options to fit your budget and needs.

How Much is a Laser Cutting Machine for Different Materials

Laser cutting machines come with different prices based on the material you’re working with. You might need a laser cutting machine for metal for heavy-duty tasks, a laser cutting machine for wood for crafting, or a laser cutting machine for fabric for fashion design.

The prices can go from a few thousand dollars to tens of thousands. Here are some key points to think about when picking a laser cutting machine for your material:

- Power and speed: A more powerful machine can cut through thicker materials but costs more.

- Resolution and accuracy: For detailed designs or small details, you need a machine with high precision.

- Material compatibility: Ensure the machine works well with your material, whether it’s metal, wood, fabric, or others.

Here’s a rough idea of what you might pay:

| Material | Machine Cost | Operating Cost |

|---|---|---|

| Metal | $10,000 – $50,000 | $500 – $2,000 per year |

| Wood | $5,000 – $20,000 | $300 – $1,000 per year |

| Fabric | $3,000 – $10,000 | $200 – $500 per year |

The price of a laser cutting machine varies based on your specific needs. Research and compare machines to find the right one for your budget and project.

Factors Affecting Laser Cutter Prices

Buying a laser cutting machine involves looking at several factors. Knowing these can help you make a smart choice. The type of laser, power, and features are key to the price.

The cost of a laser cutting machine can change a lot. This depends on what you plan to use it for. For instance, a machine for cutting metal costs more than one for wood or acrylic. Other things like precision, speed, and software also play a role.

- The brand and quality of the machine

- The warranty and support offered by the manufacturer

- The training and installation costs

By thinking about these factors, you can choose wisely. This way, you’ll get the most value for your money.

Hidden Costs and Additional Expenses

Investing in a laser cutting machine comes with hidden costs. These can add up over time and affect your budget. Regular maintenance is key to keep the machine running smoothly and extend its life.

Important costs include consumables like replacement parts and materials. You’ll also need to budget for software and training. Knowing these costs helps you plan and budget better.

- Maintenance contracts and support services

- Upgrade and replacement costs for parts and software

- Training and certification programs for operators

Understanding these costs helps you make a better investment choice. It ensures you get the most out of your laser cutting machine.

Financing Options and Return on Investment

When you’re looking to buy a laser cutting machine, you have a few financing options. You might be thinking about leasing versus buying. Leasing can mean lower costs upfront and more flexibility. On the other hand, buying can save you money in the long run and give you full ownership.

It’s important to figure out the return on investment (ROI) before making a choice. You need to think about the machine’s cost, upkeep, and how it will improve your work. A good ROI comes from using the machine well and cutting down on waste.

Here are some key things to think about when looking at financing options for laser cutting machines:

- Initial investment: The cost of the machine and any extra features or accessories.

- Operating costs: The ongoing expenses like maintenance, repairs, and supplies.

- Productivity gains: How much more you can do and how efficiently with the machine.

By carefully looking at these points and your financing options, you can make a choice that fits your business needs. This choice should also give you a good return on investment.

Don’t forget to consider the total cost of owning the machine. This includes things like training and software costs. By looking at all the costs, you can make sure your investment is worth it. It will help your business succeed in the long run.

| Financing Option | Advantages | Disadvantages |

|---|---|---|

| Leasing | Lower upfront costs, flexibility | Higher long-term costs, no ownership |

| Buying | Long-term savings, ownership | Higher upfront costs, maintenance responsibilities |

Tips for Choosing the Right Machine for Your Budget

When picking a laser cutting machine, think about what you need. You want something that fits your budget and meets your requirements. Consider the materials you’ll work with and how precise you need to be. This helps narrow down your choices to find a budget-friendly laser cutting machine that’s right for you.

Here are some key things to keep in mind:

- Type of material: Different machines are made for specific materials, like metal, wood, or fabric.

- Level of precision: For high precision, look for machines with advanced features like CAD software.

- Features: Think about what you need, such as cutting speed, accuracy, and how easy it is to use.

By thinking about these factors, you can find an affordable laser cutting solution that fits your budget. Don’t forget to consider the long-term costs, like maintenance and repairs.

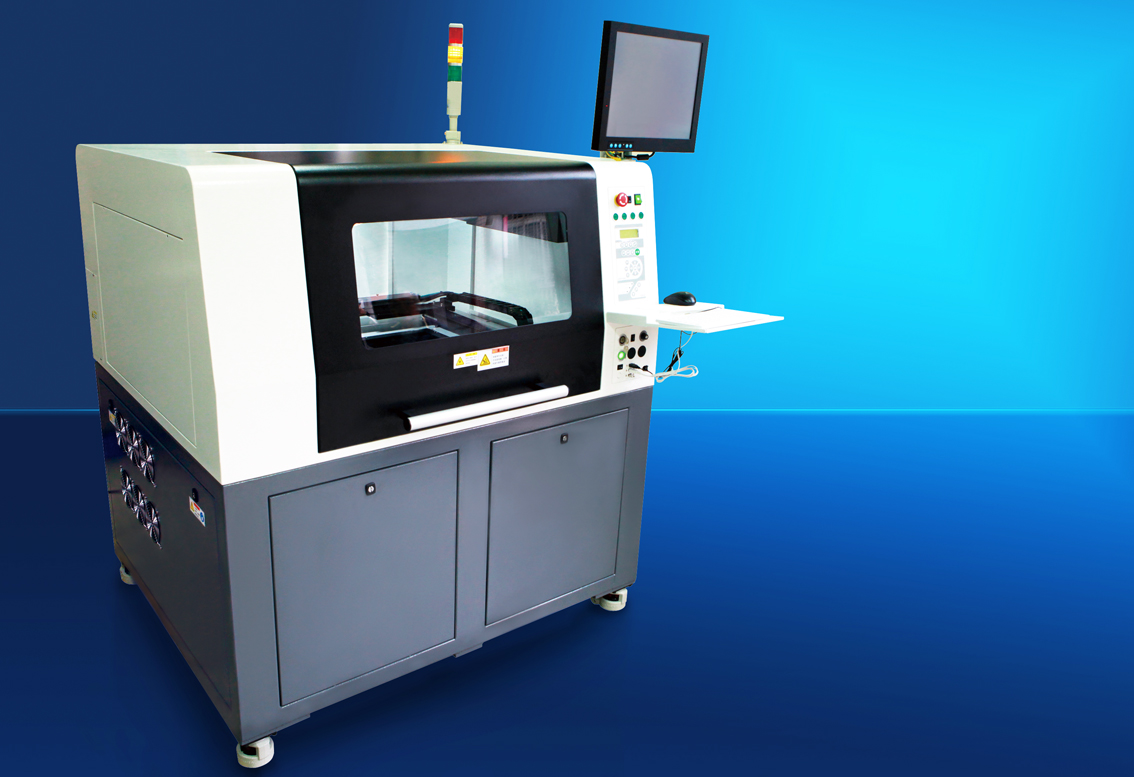

Our Recommended Laser Machine

If you’re looking for top-quality performance and reliability, we recommend LTT Corp’s laser machines. Built with cutting-edge technology, these machines offer precision and durability for all your laser cutting, engraving, and marking needs. Whether you’re in manufacturing, design, or any other industry, these machines are designed to help you achieve the best results.

Conclusion

Starting your laser cutting machine investment requires careful thought. Knowing the laser cutter purchase costs, features, and uses is key. This helps you choose the right machine for your budget and goals.

The laser cutting technology investment is big, but it opens up new chances. The right machine can boost your business.

Don’t just look at the initial cost. Think about ongoing costs, maintenance, and training too. By doing your homework, you can make sure your investment pays off.

Whether you run a small business or a big industrial operation, the right laser cutter can change the game. This article has given you the tools to make a smart laser cutter purchase. It will meet your needs for a long time.

FAQ

What is the cost of a laser cutting machine?

The price of a laser cutting machine varies a lot. It depends on the laser type, power, and features. You can find entry-level machines for a few thousand dollars. But, professional and industrial-grade systems can cost tens of thousands.

What are the different types of laser cutting systems?

There are several types of laser cutting systems. These include Qseries lasers, slc lasers, and ilasers. Each has its own benefits and uses.

What are the key applications of laser cutting technology?

Laser cutting technology is used in many ways. It’s great for cutting and engraving metals, wood, acrylic, fabric, and leather. It’s also used for marking, drilling, and other special tasks.

What are the costs of entry-level laser cutting machines?

Entry-level machines are for hobbyists, small businesses, or schools. They cost from a few thousand dollars to about ,000. The price depends on the features and what it can do.

How much do professional and industrial laser cutting machines cost?

Professional and industrial machines cost more. They can be from ,000 to over 0,000. The price depends on the cutting bed size, power, and advanced features.

What are the costs of laser cutting machines for different materials?

The cost of a laser cutting machine changes based on the material. Machines for metal cutting are pricier than those for wood, acrylic, fabric, or leather.

What factors affect the price of a laser cutting machine?

Several things affect the price of a laser cutting machine. These include the laser type, power, speed, precision, and extra features like automation and software.

What are the hidden costs and additional expenses associated with owning a laser cutting machine?

Owning a laser cutting machine comes with extra costs. These include maintenance, consumables, operating costs, and training for operators.

What financing options are available for laser cutting machines?

There are different financing options. You can lease or buy the machine. Each option affects the return on investment (ROI) differently.

How can I choose the right laser cutting machine for my budget?

Choosing the right machine involves considering your needs, budget, and important features. Knowing what affects the cost helps you make a good choice for your needs.