What is the difference between PPI and DPI? And, how and when to use them?

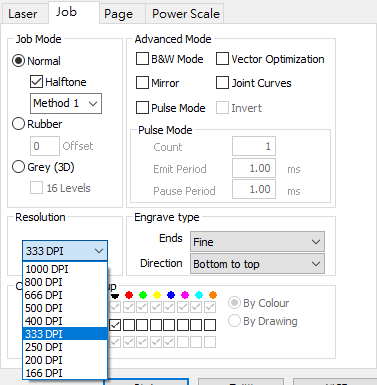

The PPI and DPI referred to here are two LTT drivers that provide functional parameters for laser cutting and engraving. "PPI" is the abbreviation of "Pulse Per Inch" (the number of laser points emitted per inch). "DPI" is the abbreviation of "Dot Per Inch" (the number of times per inch along the X-axis and the number of lines in the Y direction)

1. PPI: PPI is mainly used to determine the laser firing control method when cutting. The higher the PPI, the more frequent pulses (firing) will be, but the energy of each pulse will be relatively less, so the cutting effect will be different between different PPI values. For some sensitive materials, such as PET film kiss-cut applications, the PPI setting will be a good tool for fine-tuning power.

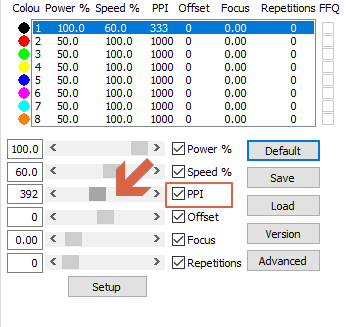

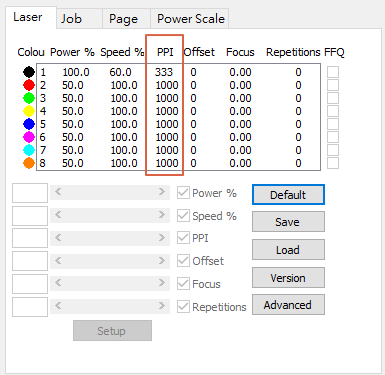

PPI parameters are located in the "laser" tab and can be adjusted through "color"