How did we get here?

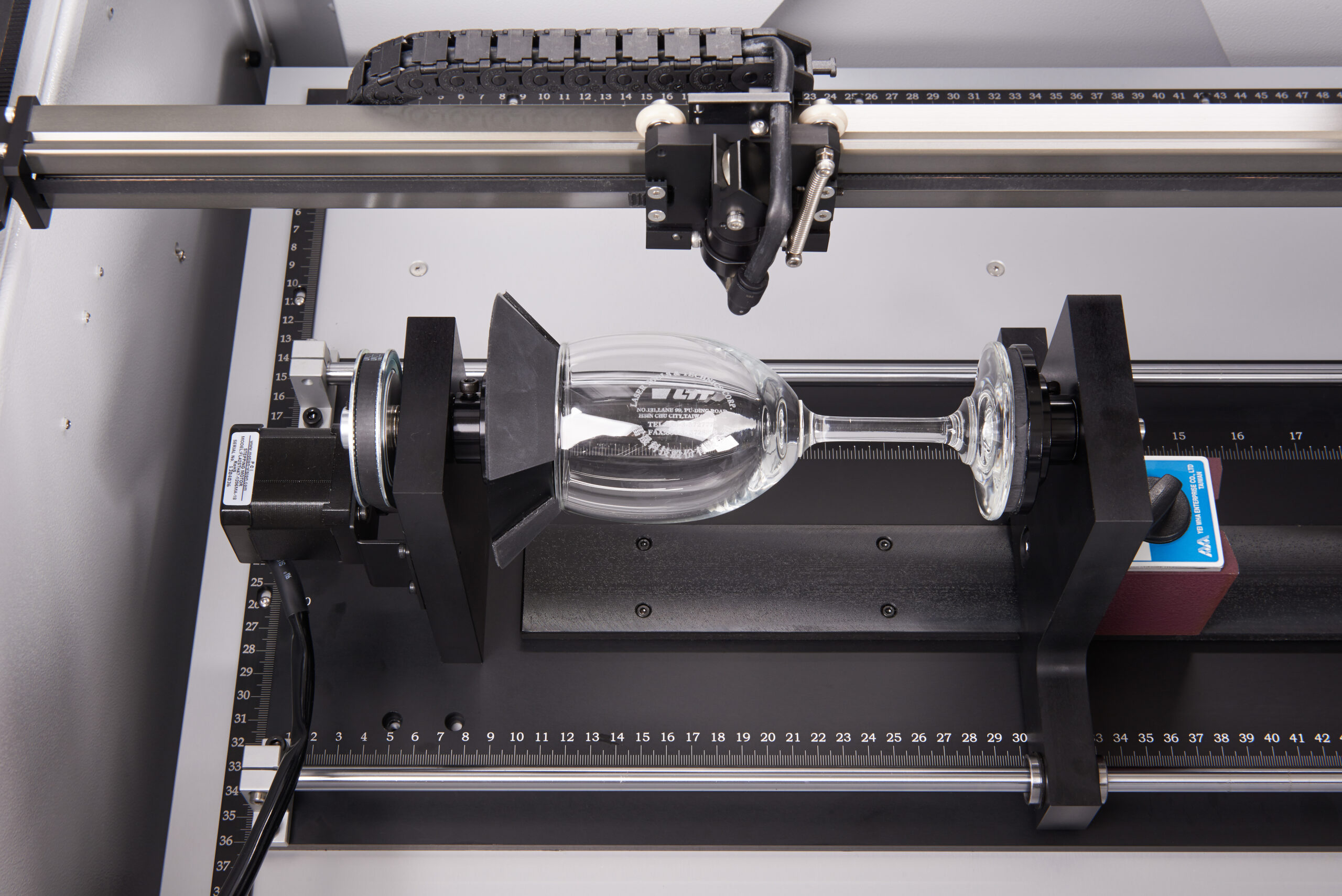

Laser Tools and Technics Corp

The Philosophy of Designing

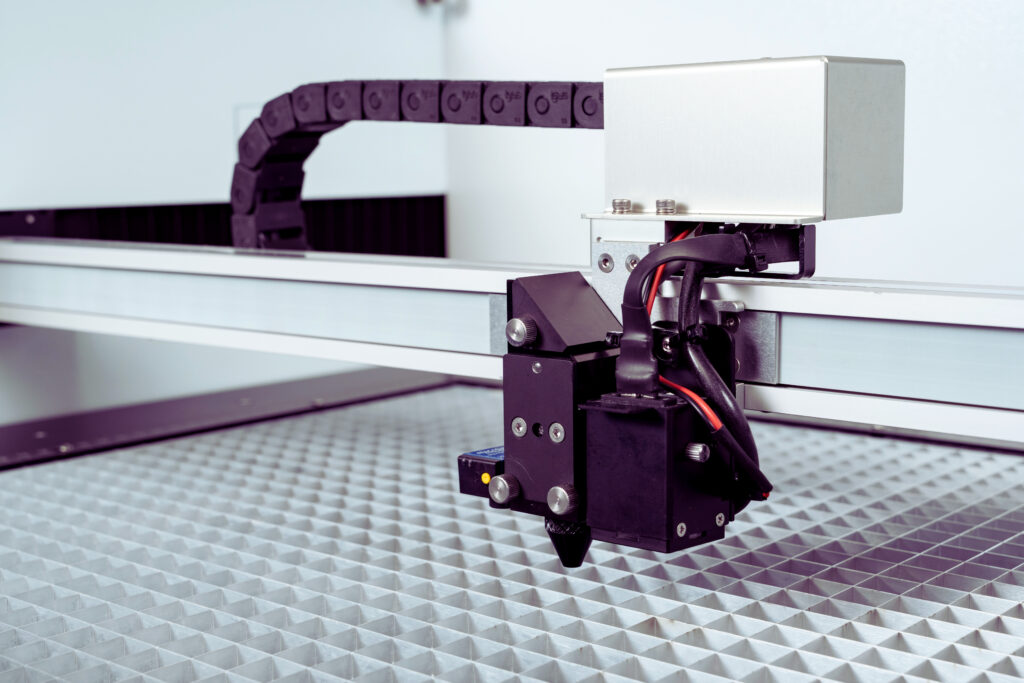

Machine Reliability is Our First Priority

For hi-tech systems, take panel industry for example. Most of the applications are from TV, cell phone, or the automobile industry. The platform of equipment needs to have a mechanism to prevent the panel from scratch. Removing fume that generated from the laser process must be carefully and thoroughly in order not to get the work object and “cleaning room” contaminated.

Some of the systems require vision devices that can recognize a specific mark to re-position the object or the edge of the object to form a cutting path. The software of the LTT system often requires to be able to do “hand-shaking” with Computer Integrated Manufacturing System to upload the producing information to the system.

All these years, many demands sent to LTT from such companies require less heat-affected effect from laser processing and minimized the processing time. That will take a lot of synergy of the work from mechanical hardware, operation, and communication software, electronic design to handle the machine/beam controlling, and fine-tuned optical design that deliver beam for individual purpose need.

Providing Software with Solution Needed

Expertise from the hi-tech work not only help us to build a machine that can deliver satisfying results of laser work, but also a device providing useful and unique features in our software that can help users when dealing various kind of materials with particular way from LTT machines.

Like control the focal length or air blow in the same work, and so on; all you need is to set up the parameters from the software and press “print” from AUTOCAD® or CORELDRAW®, etc., from your computer.